A practical overview of how 3D printing is redefining architecture—from model prototyping to full-scale sustainable construction—along with its benefits, limitations, and future possibilities.

The term architecture describes the art and science concerned with the partitioning and raising of buildings for different satisfiable needs and their chances are appealing. It accords art with technology and incorporates aspects like space, materials, climate, and culture. The purpose of architecture is not merely the erection of structures but includes the construction of the physical environment in which people live, work, and relate to each other within beautiful and solid buildings.

This article will explain how 3D printing revolutionizes architecture by enabling sustainable, cost-effective, and innovative building designs, the advantages of 3D printing architectural models, challenges and limitations of 3D printing in architecture, and the future of 3D printing and architecture.

Table of Content:

- Understanding 3D Printing in Architecture

- The Advantages of 3D Printing Architectural Models

- 3D Printing Building Construction – Changing the Future of Architecture

- Challenges and Limitations of 3D Printing in Architecture

- Future of 3D Printing and Architecture

- m. exploration

- Frequently Asked Questions

1. Understanding 3D Printing in Architecture

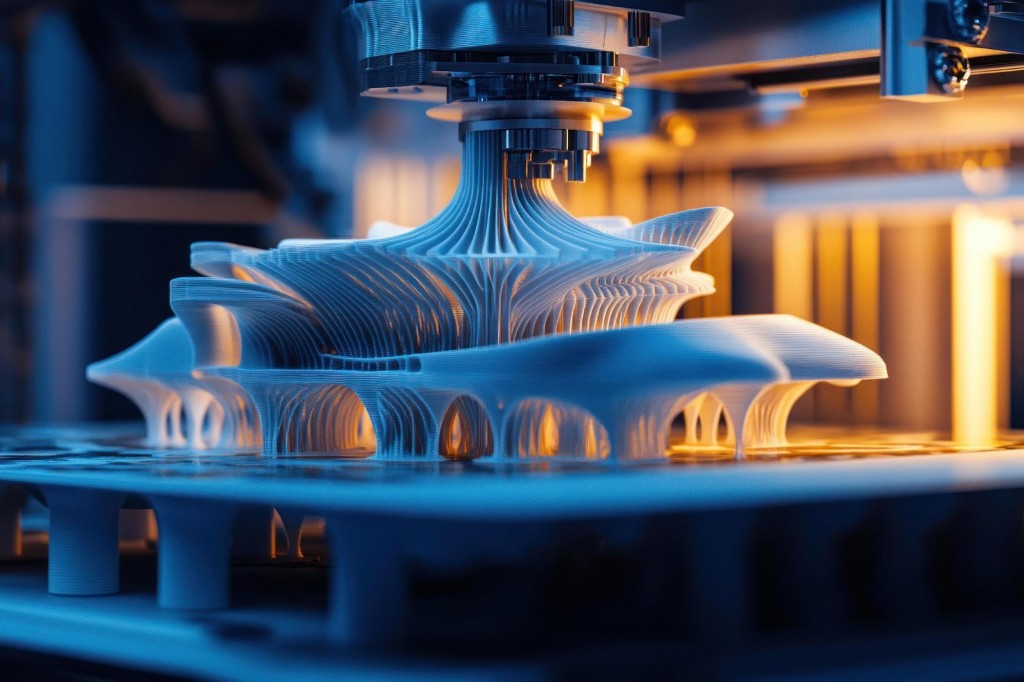

3D printing, or additive manufacturing, is reshaping the way architects think, design, and build. It offers the ability to turn digital models into physical forms, either at scale or full-size, using layer-by-layer fabrication methods. This section introduces the fundamentals of how this process integrates with the architectural design workflow.

i. What is 3D Printing in Architecture?

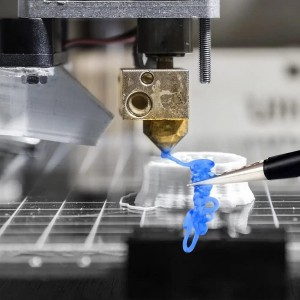

3D printing in architecture refers to the fabrication of objects—ranging from miniature models to structural components—directly from digital files. These files are generated via CAD or BIM software and interpreted by the printer’s slicing algorithm to lay down materials like concrete, polymers, or composite substances.

Unlike traditional subtractive methods (cutting, milling), 3D printing is additive—material is deposited only where needed. This reduces waste and allows for more efficient use of resources, particularly important in environmentally sensitive or cost-driven projects.

ii. How It Integrates Into Architectural Practice

Architects are integrating 3D printing at multiple stages of the project lifecycle:

- Concept Design: Rapid physical models aid in early spatial decisions.

- Design Development: Detailed prototypes help simulate joints, materials, and assembly.

- Presentation and Communication: Physical models improve client understanding and stakeholder buy-in.

- Construction: Full-scale printing of wall segments, decorative facades, or even entire structures is now feasible, particularly for modular housing and site-specific builds.

2. The Advantages of 3D Printing Architectural Models

Model-making has always played a key role in architectural practice, but 3D printing has redefined the possibilities in terms of speed, detail, and customization.

i. Rapid Prototyping

Prototypes can be created within hours rather than days. This significantly shortens design iteration cycles. Architects can:

- Visualize concepts quickly

- Identify flaws early

- Present evolving ideas to clients

- Iterate on form, function, and aesthetics without waiting for traditional fabrication

This supports a more agile and collaborative design process, especially in client-driven or competitive environments.

ii. Enhanced Detail and Customization

3D printing allows for the production of highly detailed models with realistic textures, material cues, and complex forms—such as lattice structures or parametric facades—that are otherwise difficult or too expensive to make. Custom parts tailored to specific site or user conditions can also be produced easily.

Examples include:

- Varying façade depths to optimize daylight

- Customized joinery prototypes

- Contour mapping for topographic site models

iii. Cost and Time Efficiency

Once the initial setup is complete, printing is both time- and cost-efficient:

- Automated production reduces human error and labour cost

- Minimal material waste lowers expense

- Reusable files make it easy to replicate or revise designs

As a result, even small firms or freelance architects can access high-quality, customized model-making that was once exclusive to large practices with in-house fabrication labs.

3. 3D Printing Building Construction – Changing the Future of Architecture

Beyond model-making, 3D printing is being adopted for full-scale building applications. This is revolutionizing how structures are conceived, constructed, and delivered—especially in areas such as affordable housing, disaster relief, and complex geometry construction.

1. Affordable Housing

2. Disaster Relief

3. Complex Geometry

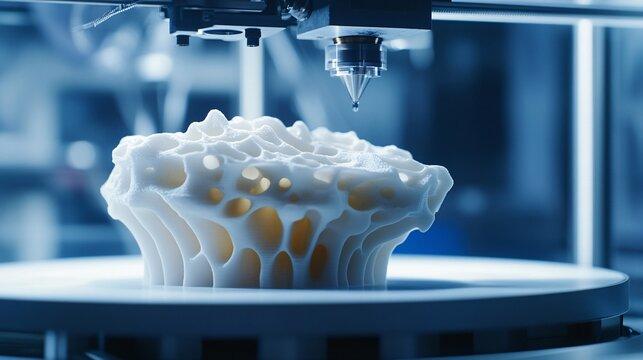

i. Large-Scale 3D Printing for Building Components

Construction-scale printers use concrete, clay, or polymer-based composites to print building parts or entire structures layer-by-layer. These are:

- Robotic gantry or arm-based printers

- On-site mobile printing units

- Factory-based prefabrication setups

Applications include walls, columns, furniture, domes, and even bridges. Companies like ICON, COBOD, and WASP have successfully delivered housing and infrastructure using these methods.

ii. Benefits of 3D Printing in Construction

Key benefits include:

- Speed: Projects that take weeks traditionally can be executed in days.

- Cost: Savings in labor and materials reduce overall project costs.

- Form Freedom: Non-linear, biomorphic, or irregular shapes are easily produced.

- Automation: Minimizes human exposure to dangerous construction conditions.

This technology is especially valuable in remote or challenging environments where conventional construction is costly or infeasible.

iii. Sustainable Construction Practices

3D printing is inherently less wasteful. By using only the necessary amount of material and enabling efficient forms (e.g., voided walls, honeycomb structures), it conserves resources. Many teams are also experimenting with:

- Recycled materials (plastic, fly ash, industrial waste)

- Bio-based materials (earth, algae-based polymers)

- Zero-waste, closed-loop production systems

4. Challenges and Limitations of 3D Printing in Architecture

Despite the promise, the adoption of 3D printing faces technical, economic, and regulatory barriers that need to be addressed.

i. Material Limitations

- Limited compatibility: Only specific mixes of concrete or polymers are printable

- Performance: Printed materials must meet building code strength and fire resistance standards

- Long-term durability: Still under testing in varied climate and load conditions

Material research is ongoing, but lack of standardized testing remains a hurdle.

ii. High Initial Costs

3D printing is inherently less wasteful. By using only the necessary amount of material and enabling efficient forms (e.g., voided walls, honeycomb structures), it conserves resources. Many teams are also experimenting with:

- Industrial-grade printers cost upwards of hundreds of thousands of dollars

- Specialist operators and technicians are needed

- Supply chains for compatible materials are still limited

This puts the technology out of reach for many small- and medium-sized firms unless accessed via third-party services or partnerships.

iii. Regulatory & Safety Concerns

- Most building codes don’t yet account for 3D-printed structures

- Structural stability, fire rating, and seismic compliance require rigorous testing

- Permits can be delayed or denied due to lack of precedent

Until regulatory frameworks catch up, large-scale implementation will remain constrained to experimental or special permit cases.

5. Future of 3D Printing and Architecture

With continued innovation, 3D printing is poised to become a foundational part of architectural and urban development strategies.

i. Material and Technological Advancements

- Smart materials embedded with sensors

- Multi-material printing: Structural + insulation + finish layers printed simultaneously

- On-site autonomous robots for live printing and assembly

- AI-driven design optimization for printable geometries

These advances will make buildings more responsive, efficient, and adaptive.

ii. Customizable, On-Demand Buildings

The future holds promise for:

- Housing tailored to individual needs

- Health-oriented spatial design (ergonomics, light, ventilation)

- Agile architecture for temporary or evolving uses

With a central digital file, architects can scale or localize structures with minimal redesign—ideal for international or remote applications.

iii. Role in Smart Cities

3D printing can play a key role in:

- Prefabricating urban infrastructure (benches, shelters, utility cores)

- Creating net-zero housing solutions

- Implementing modular, responsive public spaces

This aligns with the principles of circular economy, resilience, and urban densification.

6. m. exploration

For deeper insights into how we are applying 3D printing across design scales:

i. Material and Technological Advancements

- Visit our video gallery to see prototypes in action

- Read more at m.blogs for stories on tech integration

- Explore project pages showcasing sustainable innovation and real-world applications

- AI-driven design optimization for printable geometries

7. Frequently Asked Questions

How accurate is 3D printing?

Most architectural 3D printers offer accuracy within 0.1 mm. For building-scale prints, tolerances are larger but acceptable for most structural needs.

What are the main uses of 3D printing in architecture?

Applications range from early-stage design models and customized construction components to complete structures like homes and pavilions.

Is 3D printing cost-effective for large-scale construction?

Yes—especially for repetitive, modular, or remote builds. It reduces labor dependency, time, and material waste, though initial costs remain high.

What are its current limitations?

Material constraints, lack of building code clarity, and high startup investment are key limitations. Design-wise, extremely thin or overhanging elements may need extra supports.